Retrofit

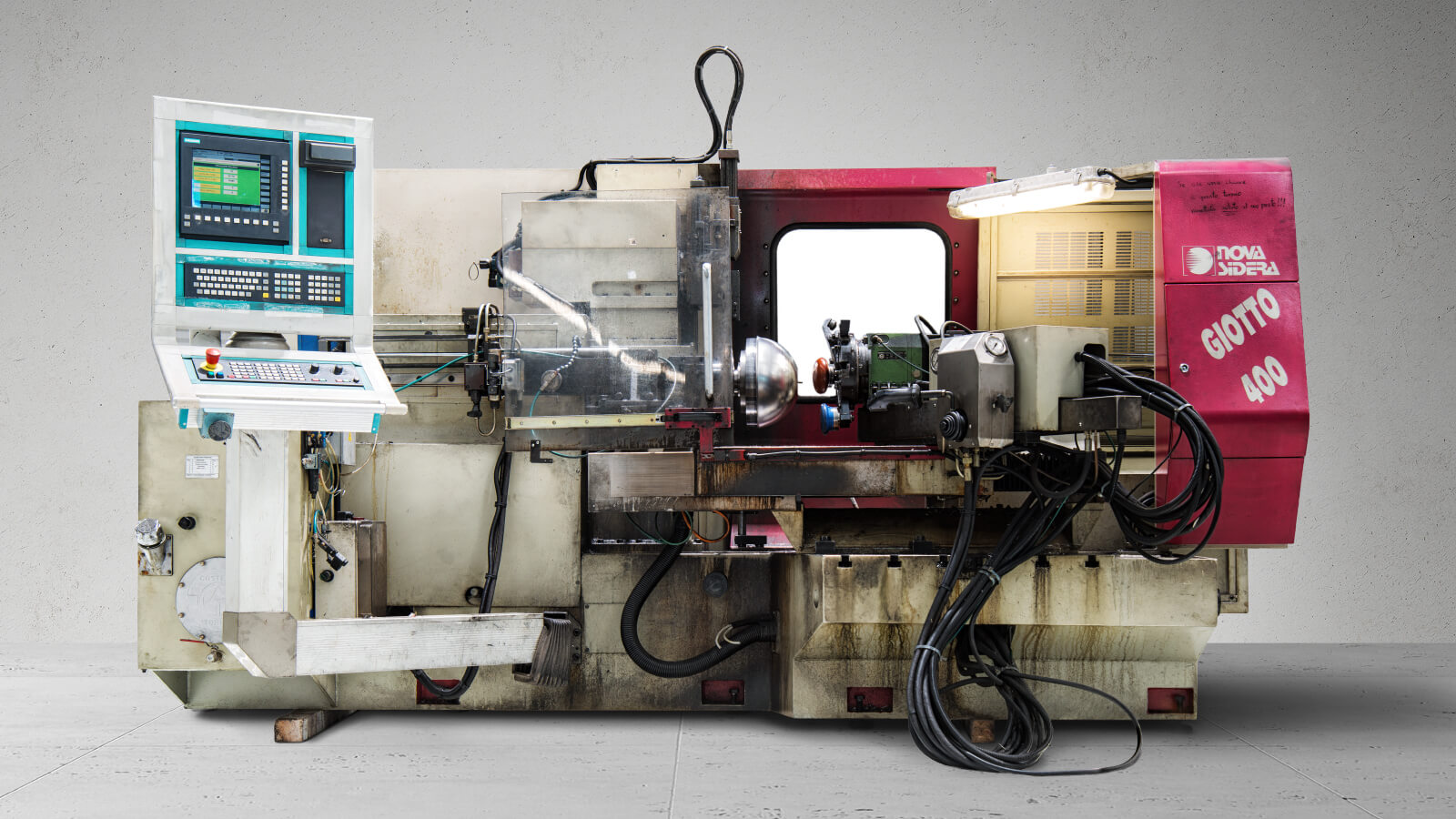

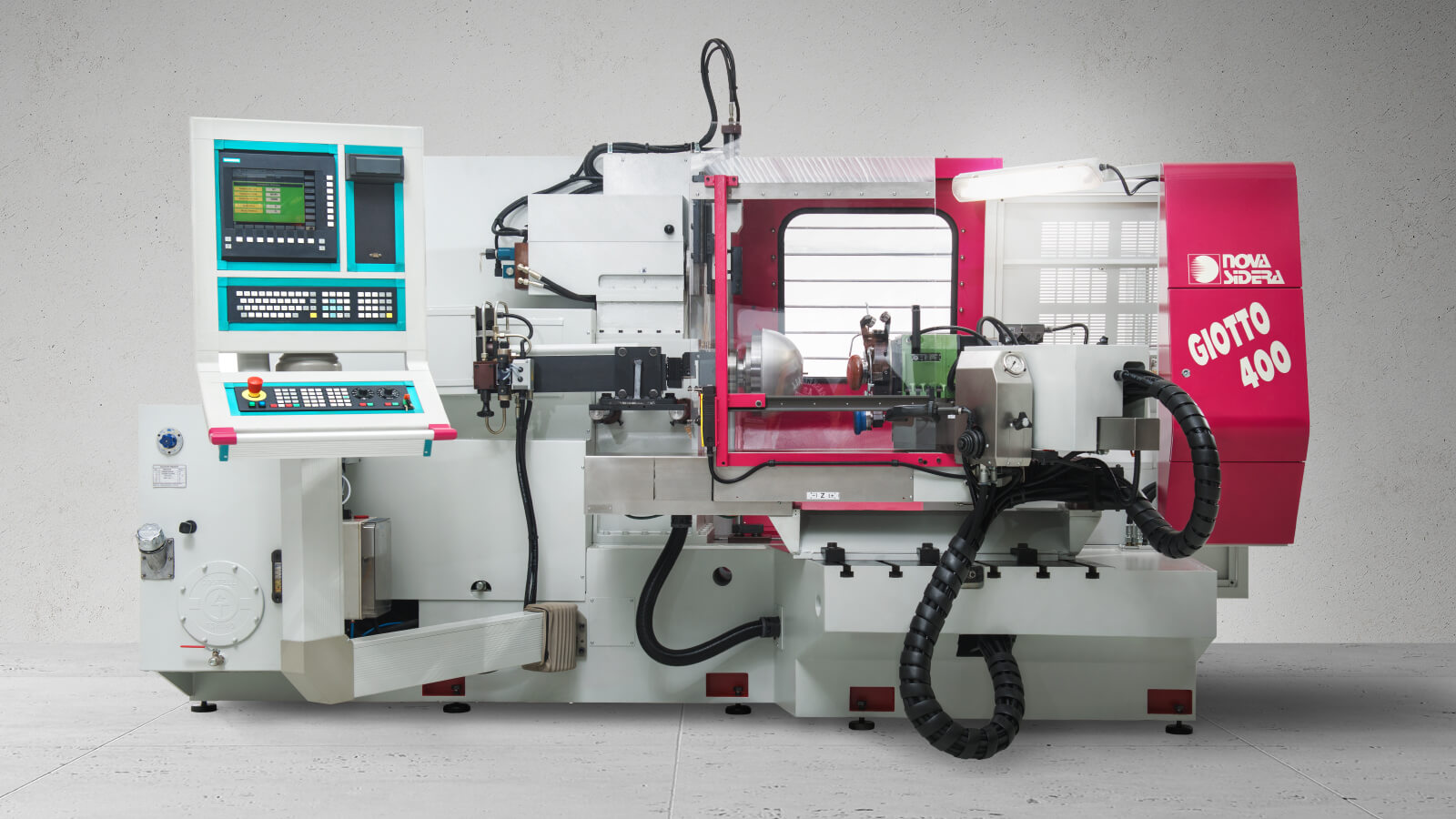

Renewing an obsolete or damaged machine

Refurbishment or revamping consists of renewing an obsolete or damaged machine. This process is crucial for restoring a dated machine and making it safe again. Nova Sidera performs this service for both its own machinery as well as third-party machinery. It consists of much more than simply disassembling and repainting the machine; in over 300 hours of work, the machine is completely disassembled into more than 2,500 components and rebuilt entirely.

List of macro activities and main features of the retrofitting process

- Check up of 2542 components of machine

- Identification of components for replacement

- Check up of all components and verification of tolerances

- Testing of single mechanical/hydraulic groups

- 92 metres of hydraulic hoses replaced

- Replacement of about 2000 metres of electric cable

- Replacement of CNC system for machines models up to 1998

- CNC upgrade for machines models manufactured since 1998

- Sand-blasting and painting of structural components

- Complete testing of retrofitted machine

- 12 month warranty

The retrofitting of Giotto 400

In the video below you can see the process of the retroffint of Giotto 400, machines with 40,000 worked hours and sold back from customer perfectly functioning